Allied Rongda Enterprises is located in Jingwei industrial development zone ,Beifang Town , Huairou District, Beijing City, which owns Beijing Allied Engineering Material Co., Ltd (Beijing high-tech enterprise), Beijing Allied Rongda Engineering Material Co., Ltd Xi'an Branch, Ltd Taiyuan Branch, Beijing Allied Rongda Technology Research Institute Co., Ltd, Beijing Allied Rongda Construction Co., Ltd, Nanjing Allied Rongda Engineering Material Co., Ltd (Jiangsu Province high-tech enterprise), Chengdu Allied Rongda Engineering Material Co., Ltd.At the same time in Jiyuan, Yangquan, Tangshan and other regions have long-term cooperation on behalf of the processing base.

Allied Rongda has more than 260 professionals specialized in R&D, production, marketing and so on, with more than 50 patents (including 18 invention patents) distribute in materials and equipment, and specializing in all kinds of refractory materials, insulation materials, grouting materials and flooring materials, which are mainly applied in metallurgy, petrochemical, electric power, machinery, building materials, construction, transportation, light industry, electronics, medicine, food and other industries, and also exported to overseas.

Allied Rongda has passed ISO9001 Quality Management System certification. RD trademark was appraised as a famous brand in Beijing by“ ”and“

”and“ ” .

” .

Adhering to the principle of service “help customers solve problems with high efficiency”, and insisting on the business philosophy "High-quality personnel, Efficient management, High-quality products, High-tech service", the Group provides the customers with service of high quality wholeheartedly!

1 Casting Repair Technology of Blast Furnace Hearth

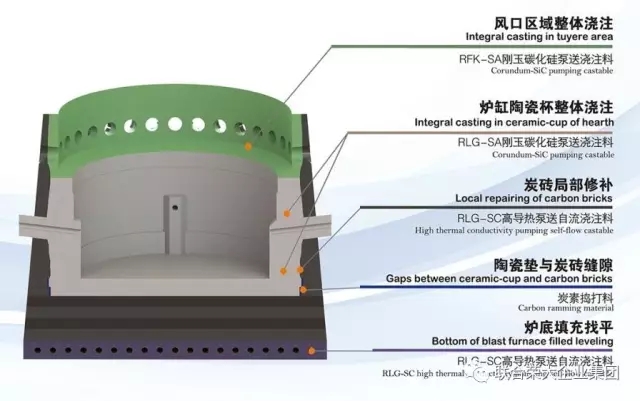

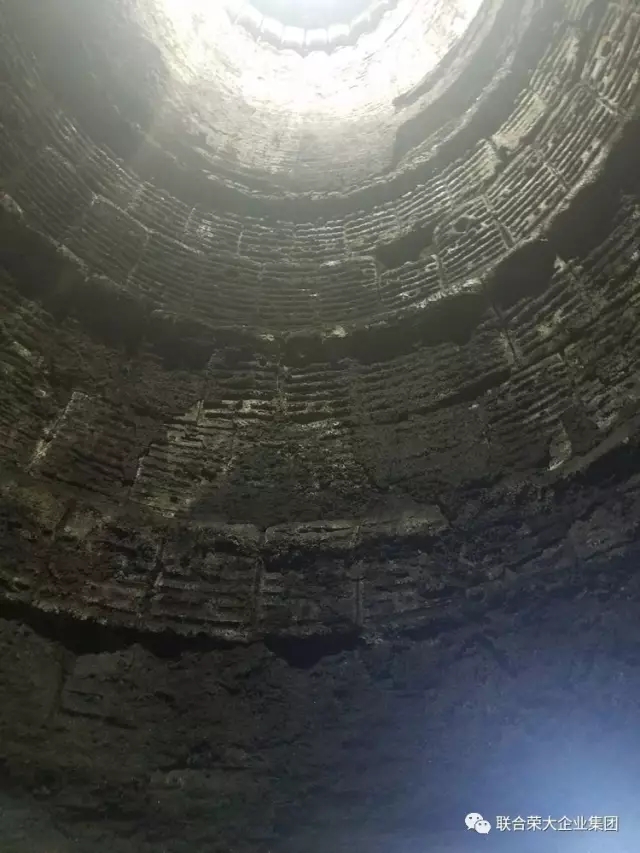

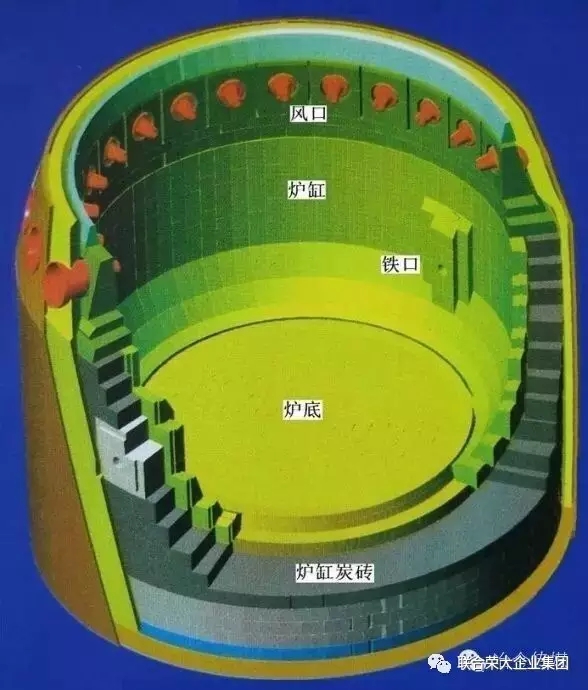

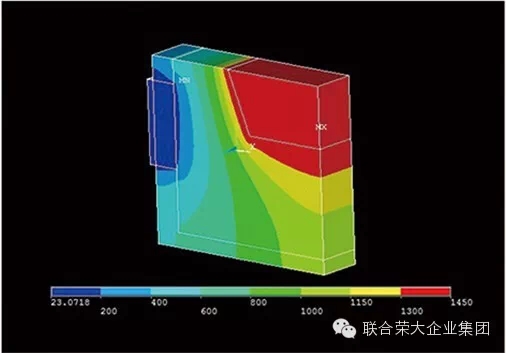

The monolithic casting repairing technology of blast-furnace hearth is a new technology by which the ceramic-cup of blast–furnace hearth and the safe heat transfer structure can be rapidly reconstructed. On the final term of hearth using, the initial ceramic-cup disappeared, and the carbon bricks are thinner than before due to corrosion, wear and erosion. The heat transfer intensity increases, and the carbon brick contact directly with molten iron. So there are hidden dangers of iron leakage because of constant dissolving of the thinner carbon bricks. A whole and seamless ceramic-cup that can withstand high temperature and slag corrosion and do not dissolve in metal iron is casted on the thinner ceramic-cup by this technology. The ceramic-cup stops carbon bricks to contact with molten iron. It can not only prevent carbon dissolving but also reduce the heat transfer intensity of hearth. The 1150°C congeal iron isotherms is pushed to the inner surface of ceramic-cup. A dynamic and stable layer with a certain thickness is formed to protect the refractory and extend the using life of hearth.

The system solutions of integral casting repairing technology of blast-furnace hearth

Refaractories、equipment and installation

The sol-bonded corundum-SiC pumping castable is developed as per the technological environment of blast furnace hearth. The castable can be pumped and has many application advantages, such as high anti-dregs iron corrosiveness and anti-dregs iron erosion. The conductive capacity of high thermal conductivity castable that is used in repairing of carbon bricks is close to that of micro-pore carbon brick.

Allied Rongda enterprises has more than 10 sets of high efficient continuous mixers and pumping equipments, and professional construction teams. We can complete the repairing of hearth quickly. The pumping efficiency can be more than 15t/h.

Technical and Economical Advantages

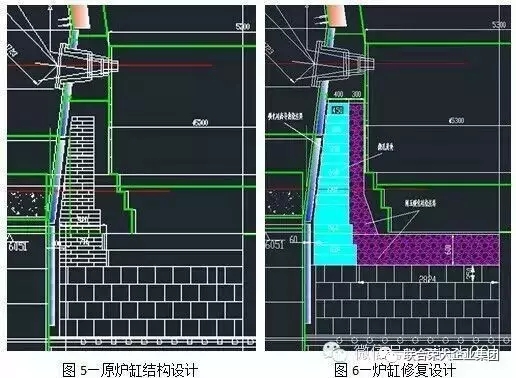

1、The re-organized structure of hearth repaired is thin-walled carbon brick+ceramic cup, the conductive system of hearth is more effective and reasonable.

2、The casted ceramic cup sticks with carbon bricks. This prevent the thermal resistance increasing caused by gaps because of shrinkage of the traditional ramming material between ceramic-cups and carbon brick layer.

3、The structure of ceramic-cup by this method is monolithic, much better than brick system which consists of countless seams.

4、We just need to tear down the carbon bricks damaged seriously and repair the hearth locally. By this way, the residual carbon bricks can be used mostly, so the material consumption reduces.

5、The efficient pumping installation process and anti-explosive performance of castable, which permits quick drying, assure the repairing project being finished within a week or so.

Application

The monolithic casting repairing technology of blast-furnace hearth can be used in the rebuilding of ceramic-cup (ceramic wall and bottom)、the repairing of taphole、casting in tuyere area (instead of tuyere combined bricks).

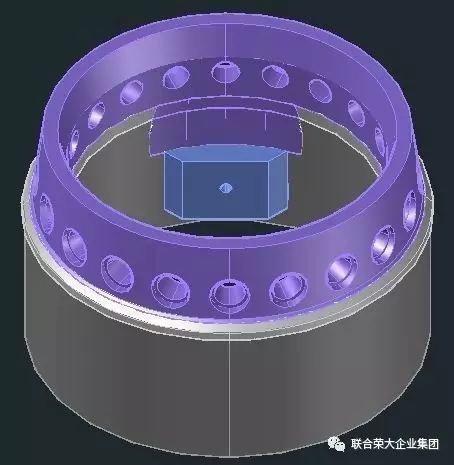

Hearth structure

Casting Model of Ceramic Cup and Tuyere Zone

Design Diagram

Technical Proposal Exchange

Technical Disclosure Before Installation

Casting Ceramic Pad

Casting Ceramic Pad

Casting Ceramic Pad

Curing

Casting Elephant Foot Zone

In Casting

In Casting

Taphole Zone

Strengthening of Formwork in Taphole Zone

Tuyere Zone Casting

Tuyere Zone Casting

Tuyere Casting

Tuyere Casting

Stripping

Stripping Mainentance

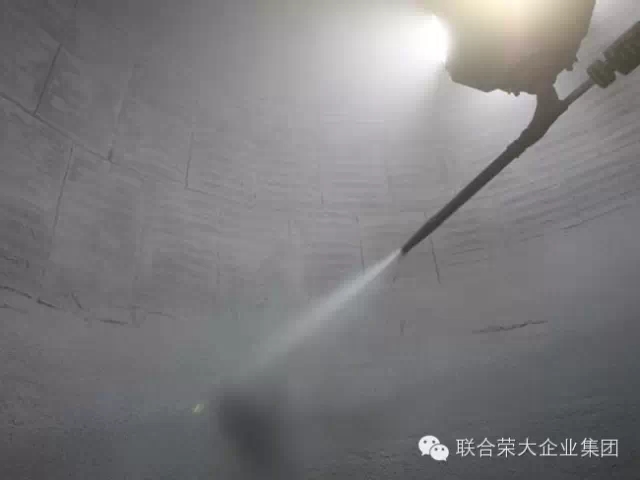

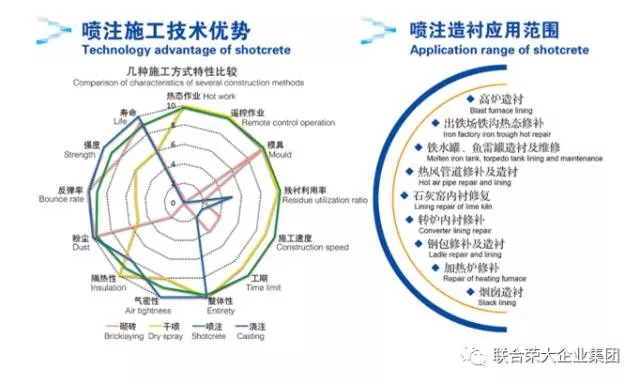

2 Shotcrete Technology of Blast Furnace Lining

▎Problems existed in blast furnace maintenance↘

Cooling stave after brick broken

BF cannot smooth running

High energy-consumption(High Coke Ratio)

High difference in water temperature

▎Problems existed in gunning↘

The material structure is loose and low strength, and the service life is short

A high rebound rate (20 ~ 30%) leads to the difficulties in blow on

High rebound rate, waste materials

Installation dust is big

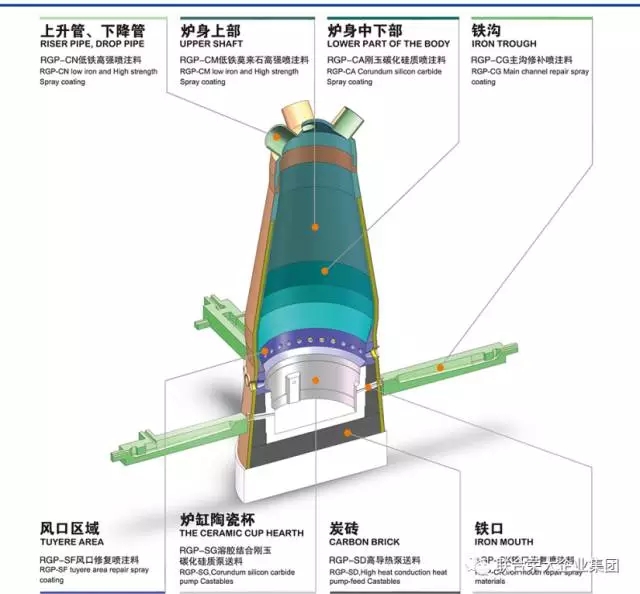

Material selection and proposal design of blast furnace lining technology in Allied Rongda can be applied to different parts of BF

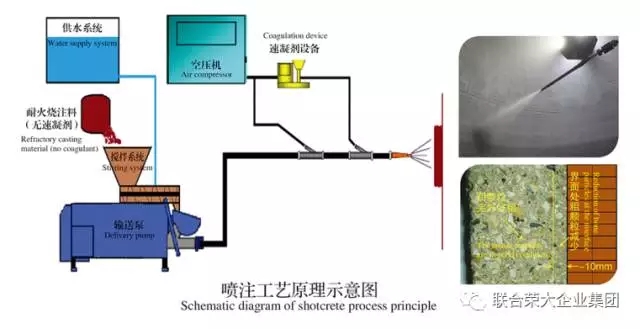

▎Principle of shotcrete installation technology↘

喷注=喷涂法实现混凝土浇注(Shotcrete=Shot Concrete, Concrete Casting by Gunning Method)

Premixed self-flowing material, through the pipeline to the gun, introducting with accelerator and high-pressure air near the nozzle, the self-flowing material is ejected, at the same time, mixed with the sufficient atomization accelerator, loss the fluidity immediately, adhesion to the substrate surface and fast curing.

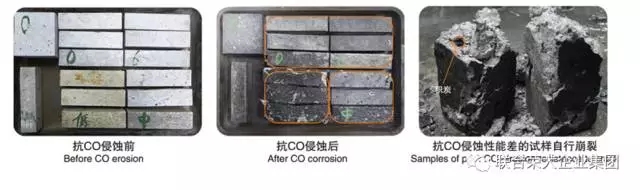

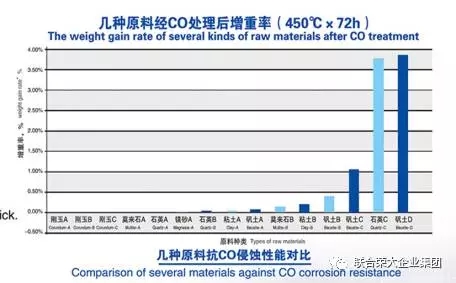

According to different parts, can choose different design properties of materials: the upper material of blast furnace need to be with high strength, high wear resistance, good impact resistance, anti erosion performance of CO; the shotcrete material at the lower part of blast furnace needs high temperature resistance, corrosion resistance to slag and iron and easy formation of slag and iron protection. Tuyere shotcrete repairing can repair or completely replace the damaged tuyere composite brick.

▎Technical Engineering Team↘

Allied Rongda has 5 professional engineering team, 10 sets of professional equipment, can be installation in different places at the same time; In order to ensure the quality of the project, Allied Rongda adopts the specially developed 4G transmission technology to broadcast the live working conditions. The front and rear technical experts are fully involved and cooperate with each other to ensure the best quality of the project !

Up to May 2017, shotcrete lining technology has been successfully applied to more than 280 blast furnaces (180-4038m3) at home and abroad.

▎Our Attitude↘

As a result of one-time cost reason and cognitive difference, many projects are still using gunning. Our company strives to promote comprehensive shotcrete, on the one hand to improve the quality of the project, longevity and durability, on the other hand, it is also conducive to emission reduction and environmental protection.

In fact, in the future, the installation of monolithic refractory materials will mostly be done by shotcrete to achieve the casting without mold or even 3D printing !

Expert seminar on shotcrete technology

On line gunning project of BF

On line shotcrete project of BF

On line shotcrete project of BF

BF full lining shotcrete project

BF full lining shotcrete project

Shotcrete Project of 4038 Giant Blast Furnace Lining in Angang Bayuquan

Shotcrete Project of 2500 Blast Furnace Full Lining in Shougang Shuigang

Shotcrete Project of 2200 Blast Furnace Full Lining in Anyang steel

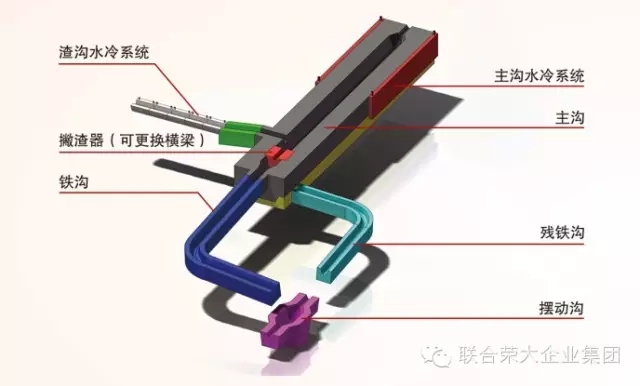

3 Iron Store Trough Full Maintenance

In 2008, successful developed the patented technology "Improvement of Iron Store Trough for BF with single taphole".

Has created Iron Store Trough for BF with single taphole transformation first at home and abroad

Up to now, a total of more than 110 iron trough have been reformed

▎Process Characteristics↘

No delay, install when tapping, will not affect production

The hot work has little damage to the iron runner matrix

Save material and make the best use of the residual lining

The material is free of drying out, and explosion proof

BF iron store trough full mainmentance

▎Patent innovations involving iron runner (14 items) ↘

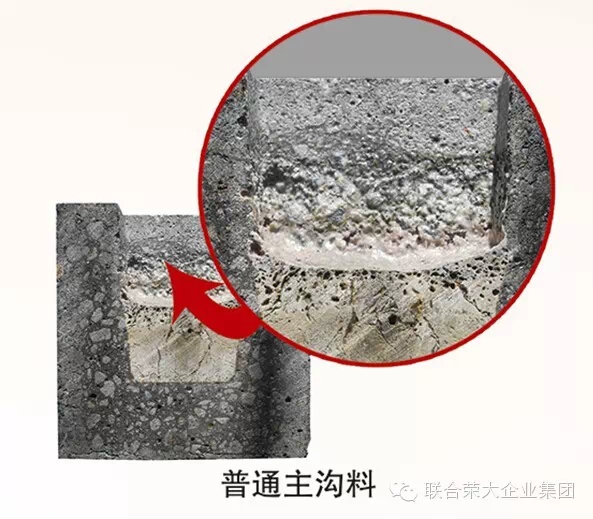

▎High slag resistance main trough material↘

▎Water cooling in main trough and slag runner↘

▎Hot shotcrete patching for iron runner ↘

Using later of iron runner (a small blast furnace with a single taphole)

Hot shotcrete patching for iron runner

Patch up

Epoxy wear-resisting floor project of blast furnace tapping yard

Epoxy wear-resisting floor project of blast furnace tapping yard

4 High Strength Wear Resistant Material

The slag runner and the granulation tower are the essential process devices of blast furnace slag treatment process, but the harsh working conditions, mainly has the following several forms of failure: acid solution corrosion; high speed water flow with material abrasion; separation of slag and iron is not the net, causing the explosion; high frequency thermal shock. Under the combined action of these four destructive mechanisms, the service life of the conventional wear-resistant layer materials can only reach a short of one or two years life, which is far from the user's requirements. Therefore, our company has set up the special wear-resistant castable for the slag runner and granulation tower. The main features of this product have high strength and abrasion resistance, erosion resistance, good acid and alkali resistance, excellent thermal shock resistance, and do not use organic binder, anti-aging and good weather resistance, safety and environmental friendship, can effectively adapt to the granulation process conditions, can be used in inner lining of slag runner of BF, EAF and Submerged Arc Furnace, wear layer of granulation tower, and various types of silo environment.

▎Installation Methods↘

According to the field application environment, we can choose four forms as prefabrication, casting, daubing and shotcrete.

According to the time schedule tight requirements or the modification of existing slag runner , you can use the form of prefabricated to install. When you use the prefabricated of slag runner which wear-resistant ceramic made by our company, it can be installed directly in the site, short duration and fast installation.

New slag runner or granulation tower is recommended for site casting and pumping, and with good integrity.

For the large installation area of the silo and others, shotcrete technology can be used. The efficiency is high, and the abrasion resistance can reach 90% of the casting process.

▎The main technical advantages of RG-MS series are as follows↘

1. Hardness higher than steel, good abrasion resistance, service life can reach more than 5 years, is two times more than the traditional cast iron trough;

2. Process is flexible, can be used with prefabrication, casting, duabing and spraying form to install according to the needs,and adapt to the environment also;

3. Good weather resistance and corrosion damage, there is no electrochemical corrosion, there is no defects of easy to aging using the organic adhesive ;

4. Using nano powder with high strength, safety and environmental friendship;

5. High cost performance, low unit cost.

RG-MS can be used for slag runner of various BF, Submerged Arc Furnace and the abrasion resistant working layers of granulation towers, can be cast in a large scale and can be used for local modification. In addition, it can also be used for the wear-resistant layer of various silo and yard environments, and the service life is greatly improved.

Prefabricated parts were produced at Allied Rongda Nanjing Co. and were waiting for loading

Prefabricated parts were produced at Allied Rongda Nanjing Co. and were waiting for loading

Installation site of slag runner prefabricated parts

Installation site of slag runner prefabricated parts

Installation site of slag runner prefabricated parts

Ceramic abrasion resistant material for blast furnace slag runner

Luanxian Jinma Industrial Co., Ltd. 1#630m³ and 2#850 m³ blast furnace slag runner repair project

Installation Site of Granulation Tower of 1250 BF, Yancheng Lianxin Steel

Installation Site of Granulation Tower of 1250 BF, Yancheng Lianxin Steel

Installation Site of Granulation Tower of 1250 BF, Yancheng Lianxin Steel

5 Shotcrete Technique for Lining of Chimney, Flue and Pipeline

Pipeline Shotcrete Engineering

Pipeline Shotcrete Engineering

Pipeline Shotcrete Engineering

Pipeline Shotcrete Engineering

6 Blast Furnace Lining Gruoting(Soft/Hard) Mud Series

Allied Rongda blast furnace lining grouting mud series products, mainly used for blast furnace , hot blast stove, heat pipe and other smelting equipment lining grouting, its main features: has good adhesion, expansibility, good liquidity of installation, from low temperature to high temperature with high strength, the installation body is compact and has a certain preservation.

There are four kinds of products, respectively to solve the needs of different parts lining. RY-65 for cooling stave with refractory brick of blast furnace lining repair when the refractory brick broken. RDT-55 for blast furnace tuyere and cooling plate parts grouting. RYT-1 and RYT-2 are used in the grouting maintenance of blast furnace hearth, iron notch and other parts.Hard grouted material RAP for blast furnace shaft, belly and bosh lining grouting maintenance.

Allied Rongda blast furnace lining grouting technology has been widely used in domestic blast furnace, with the accumulation of years of experience, professional technology and engineering team, according to the existing problems of blast furnace and the demand of the customer, using appropriate technology, appropriate equipment and suitable materials, achieve customer needs and problems in the end.

BF Grouting

BF Grouting

Xinjiang Bayi 2000m³COREX Direct Reduction Furnace Hearth Grouting

Xinjiang Bayi 2000m³COREX Direct Reduction Furnace and B#2500 BF Taphole Channeling Gas Control Project

Hanzhong Steel 1080 BF Hard Grouting Project

Environment of Allied Rongda Detection Center

Environment of Allied Rongda Detection Center

Environment of Allied Rongda Detection Center

Environment of Allied Rongda Detection Center

Allied Rongda Chemical Analysis Lab

Allied Rongda Building Materials Lab

Allied Rongda Atmosphere Test Area

Testing Equipment

Allied Rongda Location

Partial Honor

Partial Honor

Automatic Production Line

Finished Warehouse

Dr. Zhang Ronghui was invited to do "The Longevity of Blast Furnace Refractory Technology New Progress" Report on Ironmaking Industry Conference

Allied Rongda was invited to do it at the iron industry conference The Longevity of Blast Furnace Refractory Technical Report

Seminar on Blast Furnace Longevity Technology by Allied Rongda organization Meeting Site

Beijing Rongda Conference on Longevity Technology for Blast Furnace Jinan Conference Hall

Roasted Whole Lamb

Group Commendation Meeting

Welcome to Allied Rongda Visit