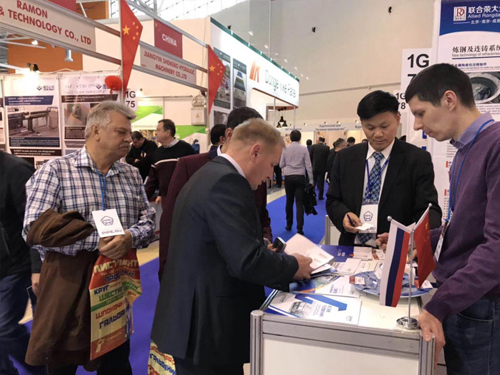

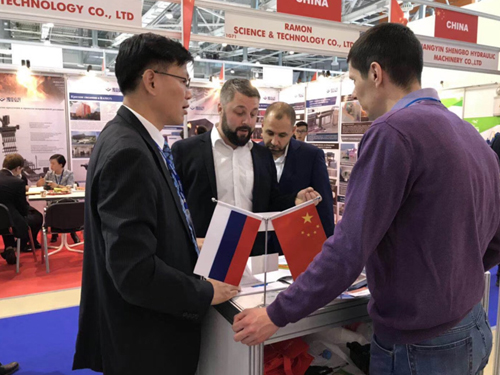

Metal-Expo’2017, 23th International Industrial Exhibition was held in Moscow from 14 to 17 November 2017. As a representative enterprise in the domestic refractory industry, Beijing Allied Rongda Engineering Materials co., ltd. ( hereinafter referred to as the " Allied Rongda " ) with outstanding products from independent research and development in recent years, along with the most cutting-edge new technologies and achievements in the metallurgical industry appeared at the exhibition, and received high attention from representatives from 69 countries and regions around the world.

Russia international metallurgical exhibition is one of the world famous metallurgical exhibition, is Russia 's largest metallurgical steel industry exhibition. With the rapid development of metallurgical industry, Russia is a big country with a strong industrial base. it also faces the problems of cost reduction and efficiency and resource, energy and environmental protection, hoping to achieve green and sustainable development. Allied Rongda with new technology, new materials and new technology invited to participate in the exhibition, has been widely concerned.

The remote control shotcrete technology of blast furnace lining not only fills the blank of the country, but also reaches the international advanced level of the same kind of technology. Through a large number of technical transformation and innovation, self-developed and manufactured suitable for blast furnace relining remote control shotcrete equipment, which made the life of domestic BF again improve fundamentally, and also made great contributions to energy saving and emission reduction in China's metallurgical industry.

"Single taphole blast furnace trough iron storage type transformation technology" is a major revolution of single taphole blast furnace. The application of this technique has remarkable effect on reducing cost, improve labor productivity, improve product quality, especially in improving labor conditions, eliminate environmental pollution is very big. Completely changed the face of the blast furnace platform dirty, messy and poor.

The environment-friendly water-based charge-pad self-flow patching material and the remote control shotcrete repairing technology of the converter are environment-friendly and efficient charge-pad self-flow materials of the converter, which basically solving all problems of the traditional patching material, greatly improving the production efficiency of the converter and realizing the effect of increasing production and increasing efficiency. The converter shotcrete repairing technology realizes the conversion of high-performance magnesia material from gunning to shotcrete material level in the converter maintenance operation, realizes the remote control of the shotcrete operation, reduces the labor intensity before the converter, and improves the service life of the converter.

Around the country "The Belt and Road" initiative, Allied brought these new technologies, new materials and new technology to Russia, hope that through these new technologies can effectively help solve the problem of the Russian metallurgical industry, high energy consumption, high pollution and high production cost.

Follow - up Allied Rongda will put Russia and other major world metallurgical industry countries into their new plans for market development, through continuous in-depth cooperation, increase investment in scientific research, to ensure the international leading position on R & D technology, and lead the refractory industry continue to move forward, contribute to the global metallurgical science and technology development, the global sustainable development of low-carbon life with China power.