New converter repair material without lung-burning air, and also reducing costs and increasing production!

The refractory materials at the charging side, tapping side and furnace bottom of the converter are under high temperature for a long time, and are subject to mechanical stress impact and repeated erosion of slag. The structure is extremely vulnerable to damage. At present, most domestic and abroad converters must be repaired and maintained at intervals to maintain the normal service life of the converter.

According to the combination system, the traditional materials used for repairing the large surface and bottom of the converter in China are mainly divided into organic combination and inorganic combination. The inorganic bonded large surface repair material has the characteristics of good high-temperature fluidity, less volatile and short hardening time. However, due to the addition of low melting point inorganic salts, the service life is not long and it is difficult to meet the requirements of site use. Therefore, for a long time, coal tar, asphalt (about 8% - 15%) and resin and other organic substances have been used as binders for large surface repair materials used for on-site maintenance of domestic converters. Among them, the asphalt system has good fluidity, the resin has excellent slag erosion resistance, the on-site workers are easy to operate, and the converter is quickly replenished, but there are problems of long sintering time. No matter what kind of organic binder, there are inevitably the following problems: 1) after the organic matter is burnt out, the material has many pores and poor compactness, which leads to the slag erosion resistance, low strength and short service life; 2) The combustion of organic matter produces a large amount of harmful flue gas, which seriously pollutes the environment of the site and has a bad impact on the health of workers in front of the furnace. Therefore, with the continuous improvement of the national requirements, the promotion and application of the environment-friendly carbon free "water-based" flow material is bound to be the general trend of the whole industry.

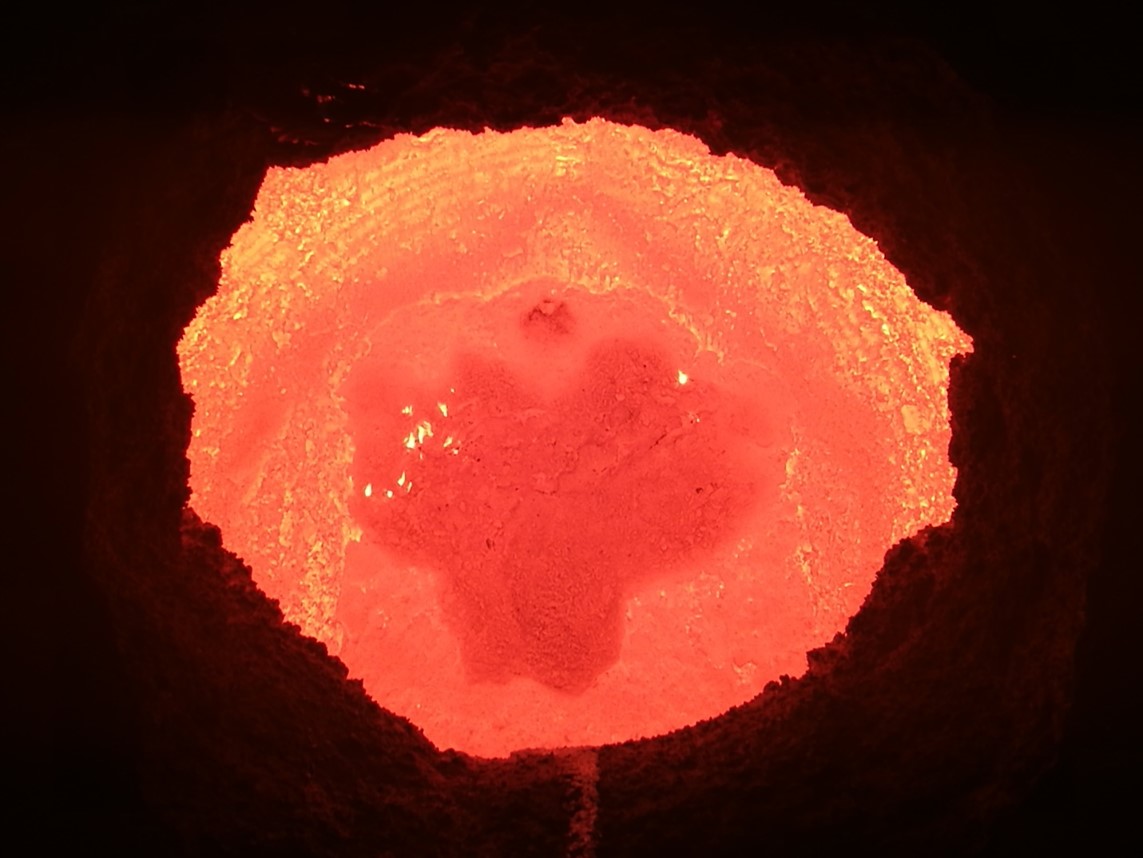

The environment-friendly "water-based" converter large surface self-flowing material is a new type of furnace repair material, which can be used for the maintenance of the front and rear large surfaces of the converter and the furnace bottom. Compared with the traditional carbon based material, this material has the following characteristics: 1) it uses an environmentally friendly liquid binder, does not add asphalt, resin and other organic substances, does not produce toxic and harmful gases during the sintering process, and only a small amount of water vapor escapes, which is environmentally friendly; 2) No low melting point inorganic salt such as sodium metasilicate is added, and the ultra-fine powder technology is adopted to add a proper amount, and ceramic bonding is formed after high-temperature sintering; 3) Using compound dispersant and adding a small amount of liquid, good high-temperature self-flowing can be obtained. Once the converter is shaken, self-flowing can be spread in the converter, and the sintering time per ton of material is less than 20 minutes; 4) The structure of the material is compact, the porosity is low, and there is no potential splash caused by the sandwich layer; 5) Long service life, generally up to 3 times or more of the traditional furnace charging materials.

The self-flowing material is a dry mixed material that has been strictly proportioned and premixed. Before use, a special forced mixer shall be used to mix the dry mixed material and the liquid binder evenly according to the specified proportion. The mixed material shall be poured into the converter through the hopper and quickly flow to the parts to be repaired. After being fully sintered by the residual temperature in the converter, it can be put into use.

The converter site application practice shows that the great advantages in reducing cost and consumption, increasing production and efficiency, and environmental protection after using the environmentally friendly "water-based" material.